澳门六合彩【挂牌】 更多»

|

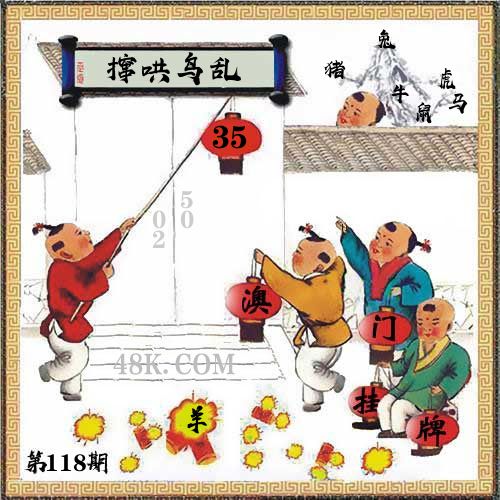

118期 | |

|---|---|---|

| 挂牌 | 35 | |

| 火烧 | 羊 | |

| 横批 | 撺哄鸟乱 | |

| 门数 | 02,05 | |

| 六肖 | 兔猪虎牛马鼠 | |

澳门挂牌解析

2024-118期正版彩图挂:35;挂牌:撺哄鸟乱;六肖:兔猪虎牛马鼠;火烧:羊

解析:【出自】:明·凌濛初《初刻拍案惊奇》第一卷:“众人起初吃酒写合同时,大家撺哄鸟乱,心下还有信有不信的意思。”【示例】:我无法适应这撺哄鸟乱的局面

解释:撺哄:起哄。乱哄哄群鸟飞舞。形容你一言我一语,嘈杂混乱。

综合取肖:牛虎蛇羊猴鸡

解析:【出自】:明·凌濛初《初刻拍案惊奇》第一卷:“众人起初吃酒写合同时,大家撺哄鸟乱,心下还有信有不信的意思。”【示例】:我无法适应这撺哄鸟乱的局面

解释:撺哄:起哄。乱哄哄群鸟飞舞。形容你一言我一语,嘈杂混乱。

综合取肖:牛虎蛇羊猴鸡

【正版澳彩图库】 更多»

澳门管家婆100282.com

『成语平特』

118期

成语爆平特

【马到成功】

开

¥00

准

117期

成语爆平特

【龙行天下】

开

龙25

准

114期

成语爆平特

【虎虎生威】

开

虎39

准

113期

成语爆平特

【狗仗人势】

开

狗19

准

112期

成语爆平特

【马到成功】

开

马35

准

澳门管家婆100282.com

『欲钱解特』

118期:

欲钱解特诗

开:¥00

《蛇鼠虎羊发大财,本期特码出大数》

117期:

欲钱解特诗

开:龙25

《虎羊蛇狗发大财,本期特码出大数》

115期:

欲钱解特诗

开:¥00

《蛇马虎羊发大财,本期特码出小数》

114期:

欲钱解特诗

开:猪18

《兔虎羊猴发大财,本期特码出小数》

112期:

欲钱解特诗

开:狗43

《鼠猪虎羊发大财,本期特码出大数》

澳彩图库心水图片资料专区

澳彩独家高手出版精料

澳彩综合全年资料大全

澳彩资料独家精准四肖

| 118期: ⑨肖 | 鸡牛羊猪龙狗蛇鼠猴 | ????中 |

| 118期: ⑧肖 | 鸡牛羊猪龙狗蛇鼠 | ????中 |

| 118期: ⑦肖 | 鸡牛羊猪龙狗蛇 | ????中 |

| 118期: ⑥肖 | 鸡牛羊猪龙狗 | ????中 |

| 118期: ⑤肖 | 鸡牛羊猪龙 | ????中 |

| 118期: ④肖 | 鸡牛羊猪 | ????中 |

| 117期--长期跟踪,稳赚不赔! | ||

| 117期: ⑨肖 | 狗蛇鼠兔虎猴猪牛龙 | 龙25中 |

| 117期: ⑧肖 | 狗蛇鼠兔虎猴猪牛 | 龙25中 |

| 117期: ⑦肖 | 狗蛇鼠兔虎猴猪 | 龙25中 |

| 117期: ⑥肖 | 狗蛇鼠兔虎猴 | 龙25中 |

| 117期: ⑤肖 | 狗蛇鼠兔虎 | 龙25中 |

| 117期: ④肖 | 狗蛇鼠兔 | 龙25中 |

| 116期--长期跟踪,稳赚不赔! | ||

| 116期: ⑨肖 | 鼠猴蛇兔狗羊虎马龙 | 羊10中 |

| 116期: ⑧肖 | 鼠猴蛇兔狗羊虎马 | 羊10中 |

| 116期: ⑦肖 | 鼠猴蛇兔狗羊虎 | 羊10中 |

| 116期: ⑥肖 | 鼠猴蛇兔狗羊 | 羊10中 |

| 116期: ⑤肖 | 鼠猴蛇兔狗 | 羊10中 |

| 116期: ④肖 | 鼠猴蛇兔 | 羊10中 |

| 115期--长期跟踪,稳赚不赔! | ||

| 115期: ⑨肖 | 牛狗羊虎鼠猴猪龙蛇 | 鼠29中 |

| 115期: ⑧肖 | 牛狗羊虎鼠猴猪龙 | 鼠29中 |

| 115期: ⑦肖 | 牛狗羊虎鼠猴猪 | 鼠29中 |

| 115期: ⑥肖 | 牛狗羊虎鼠猴 | 鼠29中 |

| 115期: ⑤肖 | 牛狗羊虎鼠 | 鼠29中 |

| 115期: ④肖 | 牛狗羊虎 | 鼠29中 |

| 114期--长期跟踪,稳赚不赔! | ||

| 114期: ⑨肖 | 蛇羊鸡猴龙牛马鼠猪 | 猪18中 |

| 114期: ⑧肖 | 蛇羊鸡猴龙牛马鼠 | 猪18中 |

| 114期: ⑦肖 | 蛇羊鸡猴龙牛马 | 猪18中 |

| 114期: ⑥肖 | 蛇羊鸡猴龙牛 | 猪18中 |

| 114期: ⑤肖 | 蛇羊鸡猴龙 | 猪18中 |

| 114期: ④肖 | 蛇羊鸡猴 | 猪18中 |

| 113期--长期跟踪,稳赚不赔! | ||

| 113期: ⑨肖 | 蛇鸡马兔牛羊狗猪虎 | 蛇24中 |

| 113期: ⑧肖 | 蛇鸡马兔牛羊狗猪 | 蛇24中 |

| 113期: ⑦肖 | 蛇鸡马兔牛羊狗 | 蛇24中 |

| 113期: ⑥肖 | 蛇鸡马兔牛羊 | 蛇24中 |

| 113期: ⑤肖 | 蛇鸡马兔牛 | 蛇24中 |

| 113期: ④肖 | 蛇鸡马兔 | 蛇24中 |

| 112期--长期跟踪,稳赚不赔! | ||

| 112期: ⑨肖 | 龙牛蛇猴鼠兔虎狗马 | 狗43中 |

| 112期: ⑧肖 | 龙牛蛇猴鼠兔虎狗 | 狗43中 |

| 112期: ⑦肖 | 龙牛蛇猴鼠兔虎 | 狗43中 |

| 112期: ⑥肖 | 龙牛蛇猴鼠兔 | 狗43中 |

| 112期: ⑤肖 | 龙牛蛇猴鼠 | 狗43中 |

| 112期: ④肖 | 龙牛蛇猴 | 狗43中 |

| 111期--长期跟踪,稳赚不赔! | ||

| 111期: ⑨肖 | 羊兔龙马蛇猴猪牛狗 | 狗43中 |

| 111期: ⑧肖 | 羊兔龙马蛇猴猪牛 | 狗43中 |

| 111期: ⑦肖 | 羊兔龙马蛇猴猪 | 狗43中 |

| 111期: ⑥肖 | 羊兔龙马蛇猴 | 狗43中 |

| 111期: ⑤肖 | 羊兔龙马蛇 | 狗43中 |

| 111期: ④肖 | 羊兔龙马 | 狗43中 |

| 110期--长期跟踪,稳赚不赔! | ||

| 110期: ⑨肖 | 羊牛猴猪鼠虎蛇龙鸡 | 蛇48中 |

| 110期: ⑧肖 | 羊牛猴猪鼠虎蛇龙 | 蛇48中 |

| 110期: ⑦肖 | 羊牛猴猪鼠虎蛇 | 蛇48中 |

| 110期: ⑥肖 | 羊牛猴猪鼠虎 | 蛇48中 |

| 110期: ⑤肖 | 羊牛猴猪鼠 | 蛇48中 |

| 110期: ④肖 | 羊牛猴猪 | 蛇48中 |

| 109期--长期跟踪,稳赚不赔! | ||

| 109期: ⑨肖 | 猪鼠猴羊虎龙鸡牛狗 | 狗43中 |

| 109期: ⑧肖 | 猪鼠猴羊虎龙鸡牛 | 狗43中 |

| 109期: ⑦肖 | 猪鼠猴羊虎龙鸡 | 狗43中 |

| 109期: ⑥肖 | 猪鼠猴羊虎龙 | 狗43中 |

| 109期: ⑤肖 | 猪鼠猴羊虎 | 狗43中 |

| 109期: ④肖 | 猪鼠猴羊 | 狗43中 |